Ik3 Series Bus Servo Drive, Servo Motor, Motor Servo, Servo 380V, 3.8kw

PRODUCT ADVANTAGESHigh Performance · Current loop frequency response > 2.5 kHz: 16-bit current sampling accuracy; dual s

Description

Basic Info.

| Model NO. | ZSD-iK3BS35EA |

| Brand | Step |

| Transport Package | Carton |

| Trademark | STEP |

| Origin | Shanghai China |

| HS Code | 9032899090 |

| Production Capacity | 5000pieces/Year |

Product Description

PRODUCT ADVANTAGESHigh Performance· Current loop frequency response > 2.5 kHz: 16-bit current sampling accuracy; dual sampling and dual update algorithms

· Speed loop frequency response > 1.6 kHz: 23-bit absolute encoder; Kalman observation algorithm

· Bus synchronization accuracy < 0.1us: Multi-axis synchronization algorithm at current ring level

· Faster servo motor speed: weak magnetic observation and control function for the servo motor to reach the maximum

speed in an instant

Great Adaptability

· Standard EtherCAT communication protocol, which can be adapted to any EtherCAT bus controller

· With detailed functions such as active resonance suppression, end jitter suppression, friction compensation, groove

torque compensation, etc., the servo performance can be perfected under various mechanical structures

· Thickened three-proof paint process for better environmental (moisture, corrosion, etc.) adaptation

Safer

· With international standard security function, SS1/SS2/SBC, safe and reliable

Easy to Operate

· Optional hand-held operation panel is available for parameter setting and monitoring of servo and motor status,

making system debugging more convenient

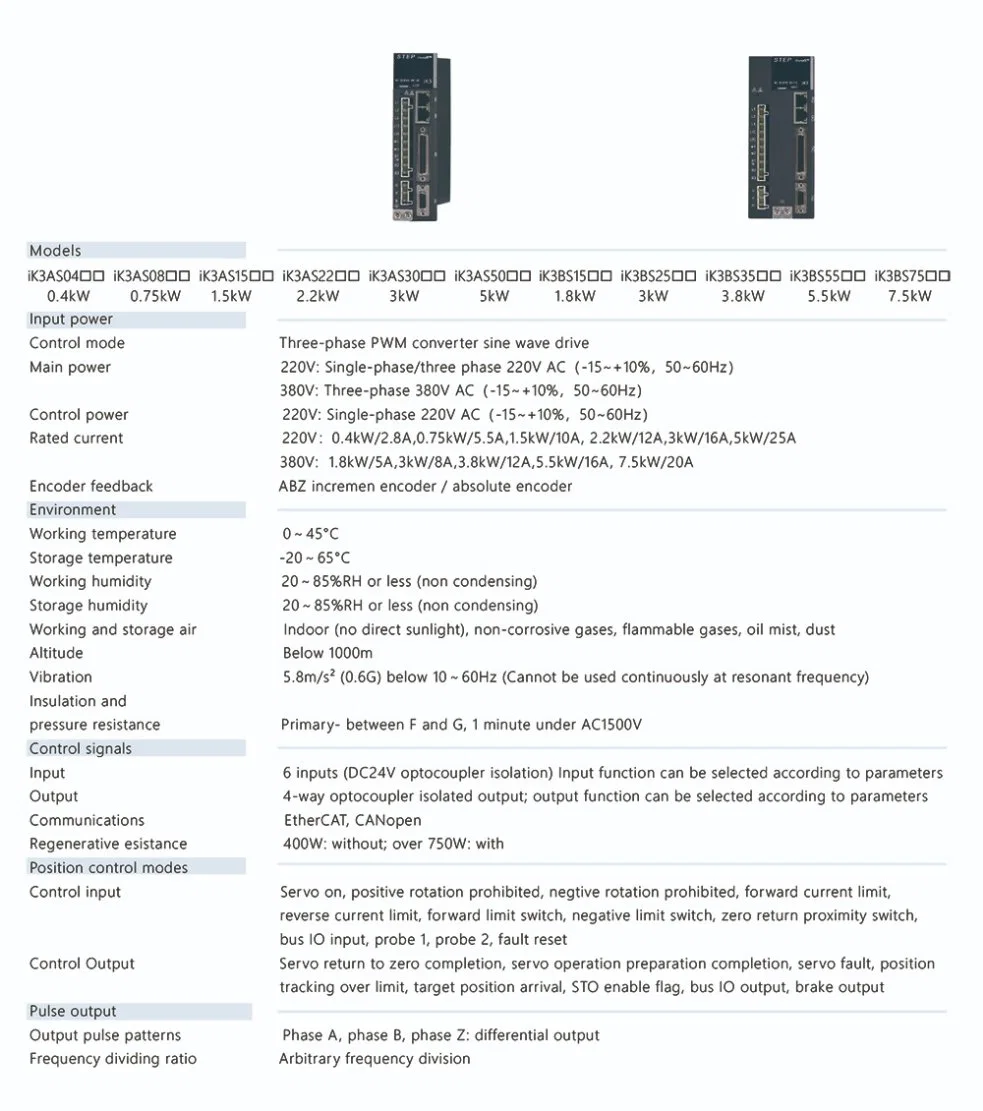

Specifications:

| Series | iK3 bus Servo Motor | |||||||

| AC 380V power level (kW) | 3.8 | |||||||

Basic specifications | Control mode | IGBT PWM control, sinusoidal current drive mode. | ||||||

220V: single or three-phase full wave rectification. | ||||||||

Encoder feedback | 2500-line incremental standard type | |||||||

17 bit incremental encoder | ||||||||

Use condition | Use/storage temperature*1 | 0~45°C (please use at a lower rate when the ambient temperature is at or above 45 °C, and the average load rate shall not be higher than 80%.)/40~70°C | ||||||

| Use/storage humidity | 90%RH below (non condensing). | |||||||

| Vibration-resistance/ impact strength | 4.9m/s2 / 19.6m/s2 | |||||||

| Altitude | Below 1000m | |||||||

EtherCAT Slave station specifications | Basic EtherCAT slave station properties | Communication protocol | EtherCAT protocol | |||||

| Support services | CoE (PDO,SDO) | |||||||

| Synchronization mode | DC-distributed clock | |||||||

| Physical layer | 100BASE-TX | |||||||

| Baud rate | 100 Mbit/s (100Base-TX) | |||||||

| Duplex mode | Full duplex | |||||||

| Topology structure | Ring and linear type | |||||||

| Transmission medium | A shielded Super 5 or better network | |||||||

| Transmission distance | It is less than 100M between the two nodes (good environment and excellent cable). | |||||||

| Number of slave stations | The protocol supports up to 65535, but there are no more than 100 in use | |||||||

| EtherCAT frame length | 44~1498 bytes | |||||||

| Process data | The maximum size of a single Ethernet frame is 1486 bytes | |||||||

| Synchronization jitter between two slave stations | < 1us | |||||||

Refresh time | The input or output of 1000 switch operations is about 30us | |||||||

| 100 servo axes are about 100US | ||||||||

| Communication error rate | 10-10 Ethernet standards | |||||||

EtherCAT configuration unit | FMMU unit | 8 pcs | ||||||

| Store synchronization management units | 8 pcs | |||||||

| Process data RAM | 8KB | |||||||

| Clock distribution | 64 bit | |||||||

| EEPROM capacity | 32Kbit | |||||||

Analog signals | Analog speed Command input | Input voltage | -10V~ + 10V | |||||

| Analog torque Command input | Input voltage | -10V~ + 10V | ||||||

Input/output signal | Figure Input signal | Signal distribution can be changed | 5-line DI | |||||

| DI function: servo drive enables forward motion prohibition, reverse motion prohibition, forward current restriction, reverse current limit, forward limit switch, negative limit switch, return zero proximity switch, bus IO input, probe 1, probe 2, fault reset | ||||||||

Figure Output signal | Signal distribution can be changed | 3-line DO | ||||||

DO function: servo return zero completion, servo operation preparation completion, servo fault, position tracking overlimit, targe location reach, STO enable sign, bus IO output, contracting brake output | ||||||||

Built-in capabilities | Over travel (OT) prevention function | Stop immediately when P-OT and N-OT act | ||||||

| Electronic gear ratio | 0.1048576 ≤ B/A ≤ 419430.4 | |||||||

| Protection functions | Over current, overvoltage, voltage shortage, overload, exceptions of main circuit, heat sink overheat, lack of one phase, overspeed, encoder anomaly, CPU anomaly, parameter anomaly, etc. | |||||||

| LED display function | Main power CHARGE, displayed by 5 bit LED | |||||||

| RS232 communication | State display, user parameter setting, monitor display, alert tracking display, JOG operation and self-tuning operation, speed, torque command signal mapping, and other functions | |||||||

| Others | Gain adjustment, alert logging | |||||||

Quality management System

- Procurement Control Procedures

- Production Process Flow

- Quality Control Procedures

Application:

· Industrial robot

· Lithium battery

· Glass carving

· Stage equipment

· Metal grinding

Company:

Laboratory:

Culture:

Award:Won the 2018 annual user satisfaction brand in the field of motion control!

Certificate:

Prev: Radiolink Prm

Our Contact

Send now